Hero friction welded chain

A new era of chains

Chains have been produced for decades using the same methodology: cutting steel wire or bar, bending them into the desired link shape and welding them together with energy intensive processes like resistance or flash butt welding.

The limiting factors of this conventional technology are the shape of the chain links (round) as well as the weldability of the steel grade, which very much depends upon the carbon content and alloying elements.

pewag hero an innovative friction welded chain goes beyond these limits and opens the door to a new world of chains.

pewag hero friction welding chain

pewag puts friction welding to the next level

Friction welding is a well understood “joining technology” which has been used by aviation and automotive industries for decades. pewag is the first chain producer to apply and refine the friction welding process for the production of the next generation of chains.

Friction welded chain is produced from forged steelcomponents, unlike round steel chain which begins with drawn steel wire or rolled bars. The use of forged components offers the ability to increase the section modulus in areas of high stress or wear and eliminates the risk of tension cracks, which can occur during the bending process of round steel chains.

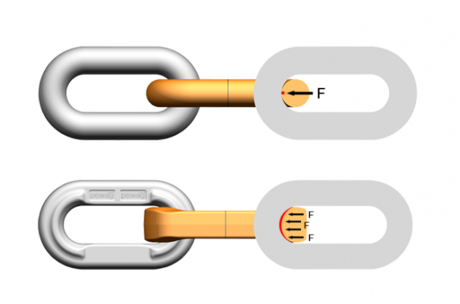

Friction welding is not a welding process in the traditional sense. Heat is generated through mechanical friction between the chain link components until the material plasticizes. A lateral force is applied to exactly fuse the components to a whole chain link.

Advantages of friction welding

1. Melt-free technique

- no grain-growth

- very small heat-affected zone (near zero residual stresses)

2. Clean joining

- contaminations between the contact surfaces will be carried away by the plasticized working mass, being pressed out during joining of the forged components

3. No material limits

- even conventionally non-weldable steel grades, for example a 50CrV4 steel which offers excellent wear resistance, can be joined

4. No shape limits

- every chain application has its special demands – the use of forged components can address critical factors like adding wear volume in the interlink section or legs of the link to drastically improve wear life of the chain

5. Reduced surface pressure & increased wear volume

- The geometry of traditional round steel chains provides a small interlink contact area and subsequent high stresses.

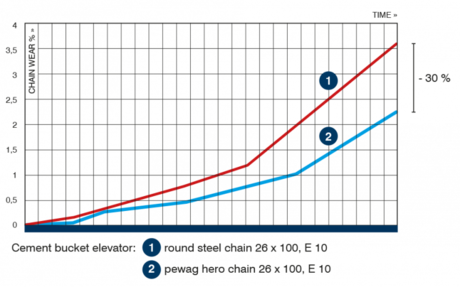

- The load specific geometry of pewag hero chain has increased interlink contact area and more than twice the wear volume of a conventional chain. This leads to significantly reduced contact- and maximum stress, better performance and approximately 30% longer service life.

Process of friction welding |

Tensile test |

Evolution of the chain ...

hand forging (18th century), electric resistance welding (since 1900) and friction welding (21st century)